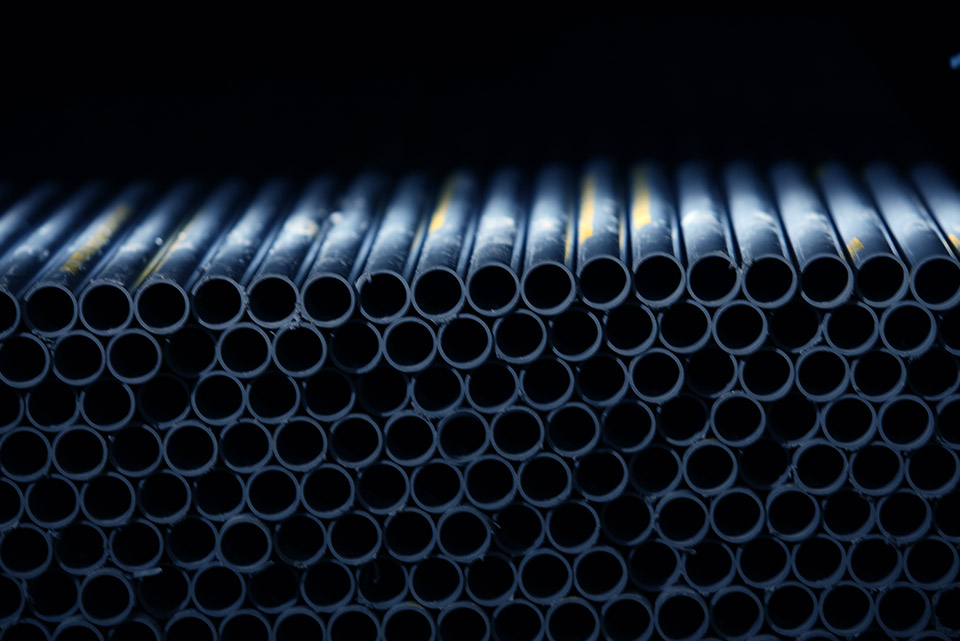

"Sharon PVC Pipes & Fittings are manufactured using the most modern technology available"

The Top Management having a vast on ground experience in the field, Sharon has a well built Organisation Structure. Our Administrative Office is well established with experienced staff’s and we strictly follow ISO work procedure.

Company plants are equipped with the most modern machineries, and sophisticated laboratory. Technical support is made available from the lead engineers in respective fields to achieve the committed quality of products to the consumers. The plant is spacious enough to accommodate multi fold expansion and addition to the production base.

Our plant is also equipped with high volume perfect dies and moulds to meet perfect product specifications and use of chilling plant in the production process to maintain uniformity for the entire range. We give utmost importance to the production infrastructures, thus distinct from others. Timely delivery of our product to the market by Sharon’s own fleet of heavy vehicles is another feather on the cap.

FEATURES OF SHARON

VIRGIN PVC

Virgin PVC Products made from high quality raw materials and High-Grade PVC constitution.

NON-FLAMMABLE

Non-flammable thus preventing the risk of a short circuit and other potential hazards.

QUALITY TEST

Our products are tested as per the requirement of IS standards, in our own lab with modern technology, to ensure that our valuable customer receives quality product”. Hence, we have proven track record and sustainability in the market for the past many years.

We strictly procure quality raw materials only from reputed raw material manufacturers, available in India, to ensure that our product complies with internal and external requirements of IS Standards.

QUALITY & TESTING PROCESS

WATER PIPES

- Composition of UPVC VCM Content, K Value

- Dimension

- (a) Diameter

- (b) Wall Thickness

- (c) Length

- (d) Socket Dimensions

- Opacity Test

- Effect on Water Test

- Reversion Test

- Vicat Softening Test

- Density Test

- Sulphated Ash test

- Mechanical Property Test

- Internal Hydrostatic Pressure

(a) Long Term

(b) Short Term - Resistance to external blow

- Internal Hydrostatic Pressure

ELECTRICAL PIPES

- Test for Electrical Characteristics

- Durability of marking

- Dimension

- (a) Diameter (Outer & Inner)

- (b) Wall Thickness

- Bending Test

- Compression Test

- Resistance to Heat

- Resistance to Burning

- Electrical Strength

- Insulation Resistance

- Impact Test

PVC FITTINGS

- Dimension

- (a) Wall thickness

- (b) Socket length

- (c) Diameter at mid point

- Performance Requirements

- (a) Stress Relief Test

- (b) Opacity

- (c) Effect on water

- (d) Short Term Hydrostatic Test

- Marking

PVC PIPES

- PVC, or polyvinyl chloride, is an incredibly common plastic used primarily in construction and as piping in water distribution systems.

- PVC is strong, lightweight and inexpensive, which is why it's so highly regarded within the building industry and by professional plumbers.

- It has many uses such as supply of potable water in residential and commercial buildings and drain lines, there are also numerous applications in the industrial field as well as farm irrigation.

- PVC Pipes can handle many different types of corrosive and other industrial fluid substances.

- PVC Conduits are widely used as electrical insulation, concealed as well as open wiring.

- PVC Pipes are also used as duct pipe in cable work.

- Some of the common usage of pvc pipes are domestic plumbing, drinking water project, rainwater harvesting, industrial usage, agricultural, irrigation, public drinking water supply schemes, electrical wiring and cabling."